Builders Responsibility

Builders Responsibility - Download PDF

Key Responsibilities

Before roof tiles can be loaded onto the roof frame, the following must be completed unless otherwise specified in the roof contract.

- The roof structure and rafters secured, square and properly braced.

- Fascia boards installed at the correct height with counter (tilt) batten (where applicable).

- Valley boards and valley irons installed in place.

- Barge boards installed with counter (tilt) battens fitted installed (where applicable).

- In the case of exposed rafters, all above rafter boarding and ceiling materials are to be installed.

- Gutters, spouting, downpipes and dry soakers installed (where applicable).

- Anti-ponding facilities installed.

- Chimneys, abutments, vent pipes and roof ventilation installed, complete with flashings and supports.

- Installation of full scaffold, guardrail or safety mesh in accordance with OH&S guidelines. If there is uncertainty about the builders’ safety requirements, contact Prime Roof Solutions.

- Clean bricklayer sand must be provided for bedding ridge and hips.

Working at Heights

WorkSafe Requirements and Safe Work Practices for Roof Tilers provides practical advice about ways to identify and manage the risk of people falling while carrying out:

- Housing construction; and

- Any other type of construction work.

Local guidelines must be referred to. A system of fall protection is required where there is:

- Potential for a person to fall working at heights.

- Where persons at or near a workplace may be exposed to the risk of injury from falls from heights.

A workplace health and safety plan must be completed detailing the control measures to be used to prevent the risk of injury.

The 4 levels of control measures, in order of preference are:

- Elimination – If you eliminate a hazard you eliminate the associated risk.

- Substitution – You can substitute something else (a substance or process) that has less potential to cause injury.

- Isolation/Engineering – You can make a structural change to the work environment or process to interrupt the path between the worker and the risk.

- Personal Protective Equipment – When you can’t reduce the risk of injury in any other way, use PPE as a last resort.

Edge protection should be used on the edge of a working platform, walkway, stairway, ramp or landing and be able to withstand the impact of a person falling against it.

Roof Frame

Wall frames and all load-bearing internal partitions must be properly framed and braced.

The roof structure must be square and straight and of dimensions true to specification. Braces should be fixed diagonally on the underside of the rafter or truss top chord.

Creeper rafters must be installed at hip corners to ensure that normal rafter spacing along the eaves is maintained. Hip and ridge boards should have their top edges level with the top of the rafters.

Please note that even a slight deviation in a roof plane will be noticeable on a finished roof and cannot be corrected by the tiler,

Exposed Rafter Counter Batten – Installed by Carpenter

In the case of raked ceiling or exposed rafters, ceiling linings, counter battens and sarking installed on top of the rafters – counter battens must be fastened over the rafter centre lines to ensure they sarking sag complies with AS/NZS 4200.2 clearance between the sarking, any insulation material and the ceiling linings.

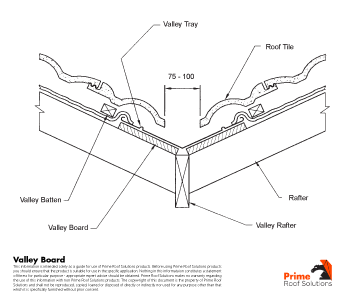

Valley Boards

Valley boards should be at least 19mm thick and installed over the ends of the valley rafters.

Valley boards and irons should be installed to finish level with the top of the tile batten, and must extend the full width of the valley.

- Valley boards must comply with Standards. Valley boards should not extend less than 220mm up each slope of the roof. Tiles should overlap each side of the valley guttering less than 100mm.

- Where there is a change in direction of a valley, a non-flammable polyurethane water based bitumen impregnated foam is recommended. Great care should be taken to ensure that valley boards and valley irons form a continuous water path to the eaves. The lip of the valley should, at all points reach the height of the roofing battens.

- Valley board thickness should not exceed 20mm where 25mm tile battens are used.

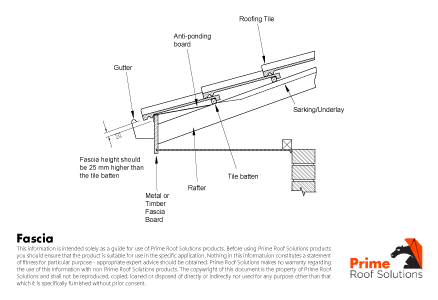

Fascia – Installed by Carpenter

Fascia board height is extremely important to ensure the last course of tiles on a roof does not dip. If the fascia height is deficient or if a fascia batten is not employed, the last course of tiles will not appear in the same plane as the remainder of the roof.

The top edge of the fascia board should be secured to the rafters 25mm higher than the tile batten thickness. For example, a batten of 25mm thickness requires a 50mm distance between the top of the rafter and the top of the fascia board. This distance is known as the fascia height.

The measurement of the fascia distance should be reduced by 10mm if the roof pitch is less than 20°. Conversely, as the pitch increases to 45°, the fascia distance must also increase.

When a fascia board is not used, or fascia height is not adequate, a batten referred to as a fascia batten must be installed. The fascia height can be calculated using the same method as above, and should be installed on the top edge of the bottom rafter.

Flashings

Flashings should be installed by a qualified tradesperson prior to tiling where possible.

Flashing should be pliable enough to be dressed down well into the tile profile with sufficient mass to retain its position under wind pressure (at least 20kg per m²).

Cover flashing should be carried a minimum of 115mm over the tile and dressed closely into the wall, watercourse and against the tile profile. The top edge should be firmly secured into the raked joints or machine cut grooves in masonry. Flashing against vertical framework must be suitably supported.

The lower edge of wall sheeting over a tiled roof must finish 90mm above the top of the tile batten to allow clearance over the tiles. The distance must be maintained for all batten sizes. Minimum clearance between top or the rafter and the bottom edge of raking, stepped or cover flashings should be 100mm. The following applies for different batten thicknesses:

| Clearance |

Batten Thickness |

| 125mm |

25mm |

| 138mm |

38mm |

| 150mm |

50mm |

Sarking around penetrations in the roof such as chimneys, shafts, vents, skylights and abutments should be trimmed and the edges turned up to divert water around the projections and from under flashings. The issue of ponding should be considered.

Builders Responsibility - Download PDF